[Update April 2019]: Just about to start our third season, and these planters are holding up really well! The wheels still roll smoothly, and no rust so far.

Want to make cool galvanized trough planters? So did I! Here’s how I did it.

Why galvanized trough planters?

Lots of reasons.

We live in an old house, and old houses tend to have lead in the soil. The nice folks at UMass tested our soil and confirmed it does, in fact, have lead. So we can’t have a normal garden in the ground.

Last year, we tried straw bale gardening. It was great, but some plants (namely basil, carrots, cabbage, a few others) did terribly in the bales.

Mrs. MakerJosh grew up with horses, and always liked the look of galvanized metal water troughs. Good old Pinterest showed us lots of ways it could be done, but no specific instructions for how to do it.

This spring, we decided to take the leap. I was going to build six galvanized trough planters. Our garden would be half galvanized trough planters, half straw bales.

The finished galvanized trough planters

Before we dive in, take a look at these beauties.

About the project

Is it hard?

You’ll break a sweat. It’s not hard, but you’re moving around a lot. You’ll need basic carpentry skills. It’s mostly drilling and screwing (#thatswhatshesaid), so you’ll need a great drill. (paid link)

Will it hurt?

This is definitely a safety glasses (paid link) and gloves (paid link) type of project. Some of the metal gets pretty sharp, and there’s dust flying around.

How long will it take?

If you’re an idiot like me, one planter will take five hours. That includes three trips to the local hardware store.

If you’re not an idiot or if you follow these instructions, each planter will take 30-45 minutes to build.

How much do they cost?

$172 per planter. Detailed cost breakdown at the end.

Galvanized Trough Planter Supplies

1) Galvanized Troughs

They’re called all different things. Is this regional? “Feed troughs,” “food troughs,” “galvanized troughs,” “watering troughs,” “stock tanks,” etc.

We tried to find a used one on our local Craigslist site, but didn’t have any luck. That’s definitely going to be your cheapest option. So start there, and try all the different name combinations above.

After striking out on used, we started looking for new. The two best sources we found were:

For the troughs that we wanted, the prices were about the same between Amazon and TSC. Since we get free delivery from Amazon and we didn’t want to rent a trailer, Amazon was the clear winner!

We ended up getting these “galvanized stock tanks” (paid link) in the 90-gallon size. Pick whichever size suits your fancy.

They took about a week to arrive. They shipped via freight instead of the typical Amazon Prime UPS/Fedex. That meant we had to be home to sign for them when they arrived.

2) Wheels

Trust me, you’re going to want wheels on these things. More on this later, but each planter was easily at least 300 pounds. If you fill the whole thing with potting soil, expect it to be over 600 pounds. They are BEASTS. If you don’t put wheels on them before filling them with soil, you’re not going to be moving them.

There’s another good reason to have wheels — drainage. If you over-water or if it rains, you won’t drown your plants since the planter is a couple of inches off the ground.

I spent a lot of time researching wheels that could handle the load and that would hold up outside. I ended up going with these: (paid link)

Here’s what I looked for in wheels:

- Ability to hold at least 800 pounds for a pack of four.

- A locking switch so the galvanized trough planters wouldn’t roll around.

- I would have preferred stainless steel or galvanized wheels. These were tough to find. My hope is that they wouldn’t rust too badly since they’ll be under the watering trough.

3) Bolts (size DOES matter)

I’ll be honest — I picked the wrong bolts. And that messed me up, bigly. Trial and error with bolts is the main reason the first planter took five hours.

Here’s the embarrassing evidence of my trial and error:

Here’s where you get to learn from my mistakes. You’re welcome.

First, I got bolts that we were too skinny. They bent, stripped, and generally made life miserable. Don’t go with anything smaller than ¼”. I ended up with ¼”-20.

(LPT: want to know what numbers like ¼”-20 means? Here’s a good article.)

Next, I got bolts that were too long. I guessed that i needed 2” bolts, and had a grand ol’ time attaching that first wheel. It was a delightful surprise when I learned that the bolts were so long that the wheels wouldn’t turn.

So I pulled out my handy folding jab saw (paid link) and cut the bolts off, and started over.

Last, I got the wrong metal. I know better. But I was in a rush. Zinc rusts. Stainless steel doesn’t. You need stainless steel.

So here’s what you want to use:

- ¼”-20 x 1-½” Stainless Steel Hex Head Bolts (paid link). Any longer than 1-½”, they’ll hit the wheels. Anything shorter, they won’t make it out the other side. You’ll need 16 per planter.

- ¼”-20 Stainless Nylon Insert Lock Nuts (paid link). Lock nuts are nice because they won’t come loose after they’re attached. Again, 16 per planter.

- ¼” Flat Washers (paid link). You’ll need 32 per planter — one for the top of the bolt and one for the nut.

4) Other stuff

Pressure Treated Wood

The bottom of the galvanized trough planters are way too flimsy to support 800 pounds.

I was lucky because I had some wood leftover from a fencing project. I found that the wood commonly used on decks (5/4” by 6”) was perfect. You’ll need 36” (three feet) for each planter.

Landscape Fabric

You’ll also need a roll of this stuff (paid link) to make sure your potting mix doesn’t just wash away.

The Right Tools

There is no way I could have done this project without these tools:

- An excellent drill/driver. I recently upgraded to this puppy (paid link) and it’s the best drill I’ve ever owned.

- Some sharp drill bits. You’ll be using the ¼” bit a lot. I also picked up this little kit (paid link), and am very happy with the quality.

- Oh my god you need this. I didn’t have the right size when I started the project. I picked one up on one of my trips to the hardware store, and it made things go so much more smoothly. These little adapters let me use a socket wrench on my drill (paid link).

- Good safety glasses (paid link) and gloves (paid link). Definitely some sharp metal and wood flying around.

- A good tape measure. I have a few of these kicking around (paid link), love the ability for the tape to stand out unsupported.

- Tape to act as a second pair of hands. This is another trick I learned along the way. This Gorilla Tape was great (paid link) because the troughs were a bit damp. This kind of tape actually thrives in slightly damp situations.

- A good socket set. For this project, it helps to have sockets that are a bit long, like this one (paid link).

Let’s get to building the galvanized trough planters!

Planter #1 took me 5+ hours. Planter #3 took me 31 minutes. YMMV.

Step 1: Gather your things

If you ordered more than one watering trough, they will come nested like this:

We thought it was odd that the troughs are slightly different sizes. Once they’re unpacked, though, we didn’t notice it at all.

Your wheels will come in tidy boxes like this:

Step 2: Cut and place your wood

Cut two 18” lengths of pressure treated wood.

Step 3: Unpack your wheels, rough layout

Place your wood and wheels in their approximate spots.

You want the wood as far as possible to the outside edge, with the corners lining up with the edge of the planter. Do this for two reasons: (1) to maximize stability and (2) so that you can reach the wheel locks with your foot.

Step 4: Mark your wheel placement

Measure 1 inch from each end of the boards to find where you’ll mount your wheels.

Center the wheel on the board at the 1” mark, then use a Sharpie (paid link) or pencil (paid link) to mark your holes.

Step 5: Get to drilling!

Re-position your board so that the corners line up with the edges of the watering trough. Put a lot of weight on the board to hold it in place, then grab your ¼” drill bit (paid link) and start drilling holes.

(LPT: go slow! You’re drilling through an inch of wood and then metal. If you’re putting the right amount of pressure on your drill, it should take 10-15 seconds for each hole).

Once you’re done with a hole, drop one of your bolts into it. That will keep it in place as you drill the other holes.

Keep drilling holes and dropping in bolts until you finish a side, like this:

Step 6: Flip the trough over (flip 1)

Take the boards off, leaving the bolts in them, and place them to the sides of the planter.

Be careful to keep them oriented in the same direction as they were when on the planter, so that your holes will line up.

Stack up a couple of your boards to raise one end of the trough off the floor. You’re going to need some room underneath for the bolts.

Step 7: Insert the bolts

Put two bolts in each side (don’t try to do all four at once — they’re actually really hard to line up). Put a washer under each bolt head.

Then cover them with a strip of tape (paid link) to hold them in place.

You’ll end up with this:

Step 8: Flip the trough over (flip 2)

Carefully flip your watering trough back over. You’ll be greeted with four friendly waving arms.

Line up your board over the bolts, and then set two of the wheels on top.

Here’s where this tool (paid link) really earns its keep:

Put washers and nuts on each bolt end and hand tighten. Then grab your drill and socket combo, and tighten those puppies down.

You want to be careful to tighten these just enough. Too much, and you’ll pull through the thin metal and the bolts will block the wheels from turning. Too little, and you’ll have wobbly galva trough planters.

Using my trusty carpenter’s folding rule (paid link), I found that having the bolt end stick out about 3/16” from the nut was perfect.

Step 9: Flip, flip, Flip-a-delphia (flip 3)

Flip your trough over again.

When you do, it’s likely that you’ll see something like this:

No worries! Just grab your drill and ¼” drill bit and re-drill the wood hole.

Then repeat the process, adding the other four bolts to the holes (with a washer on each one!), and taping them down.

Step 10: Flip it again (flip 4)

Flip your trough over again. Put washers and nuts on the remaining bolt ends, and tighten them down.

You’re now the proud owner of a half-made galvanized trough planter!

If you look inside your planter, the bolt heads should be nice and snug up against the metal. If they’re not, you may need to loosen and tighten the nuts a couple of times to draw them in.

Step 11: Rinse and repeat (flips 5, 6, 7, and 8)

You’re now going to repeat the same process on the other side:

- Rough layout of wood and wheels

- Measure 1” from the end of the board, place your wheel, and mark your holes

- Hold tight, drill slowly, dropping bolts in as you go

- Remove the boards and bolts, flip the trough over

- Pop in four bolts and washers, tape them down

- Flip the trough over, and attach two wheels with nuts and washers

- Flip the trough back over, redrill your holes, then pop in four more bolts with washers

- Flip the trough back over and put on the final nuts and washers

Step 12: Drainage

Fantastic! You should now have a galvanized trough planter that’s nearly ready for the great outdoors.

There are still a couple of things you need to do, though — it’s drainage time.

First, drill 10 holes in the bottom of the planter with your ¼” bit. Just randomly space them out.

Finally, unscrew the water plug that ships with the galvanized trough. That’s a perfect use for channel lock pliers, a plumbing workhorse in my toolbox:

Now we’re ready to head outside!

Step 13: Fill the bottom of the planter

As mentioned above, these suckers are HEAVY.

Here’s how much I weighed when I was holding a 50 quart bag of potting mix:

Here’s how much I weighed without holding anything:

(don’t worry – I’m 7 foot 4 inches. That’s a perfectly healthy weight, I’m really not overweight at all).

Each bag was about 60 pounds. It would take 6-8 bags to fill a galvanized trough planter all the way up. That’s 360 – 480 pounds, not to mention the weight of the trough itself.

Ouch!

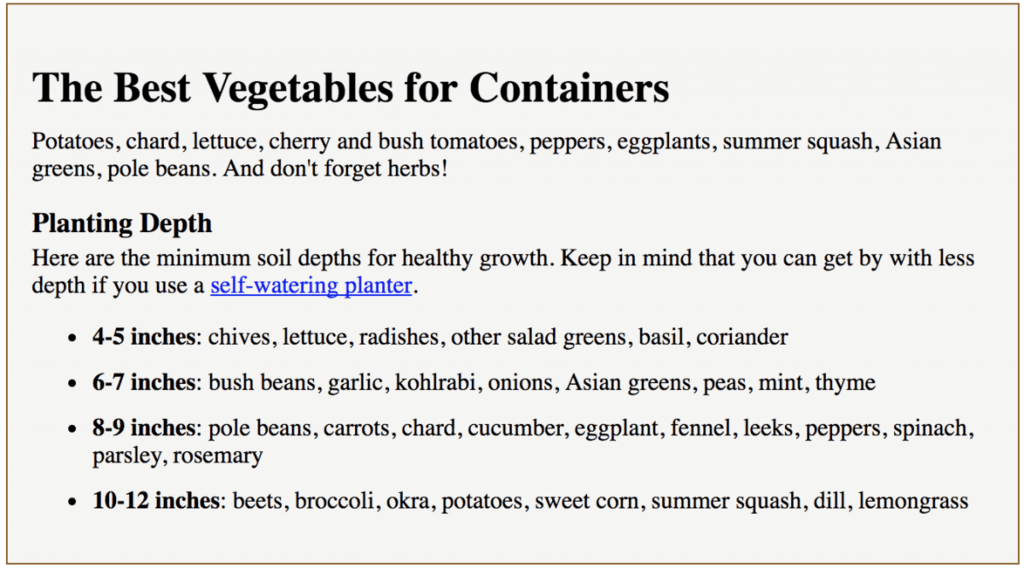

This would also be a huge waste of money, as vegetable roots don’t go down two feet. Gardener’s Supply has a great summary of how much soil you need for each type of plant:

So we could get by with soil in just half of the trough.

But what to fill the bottom with?

Lots of great ideas out there — the Yarden recommends gravel, broken pot shards or other material. ApartmentTherapy suggests soda cans. Two Men and a Little Farm talk about soda bottles or rocks.

I was in the middle of a dump run when struck with inspiration. I saw multiple people wrestling with packing styrofoam. Not those annoying peanuts, but big stable chunks of styrofoam that can pad a TV.

10 minutes later, I was the proud owner of lots of free styrofoam. I was also the subject of five people looking at me like I was crazy when I told them that I’d take their styrofoam.

I broke up the styrofoam and placed it in the bottom third of the planter, careful not to cover the drainage holes.

I made sure I had about 18” left for soil.

Then I covered the styrofoam with landscape fabric (paid link). This will keep the soil from washing away.

Step 14: Fill ‘er up

It’s time to fill it up.

I forked in a few forks of partially-composted straw (from last year’s straw bale garden):

Then I filled the remaining space up with potting soil, leaving an inch or two at the top. It took 3-½ 50 qt. bags of potting mix to fill up top of each galvanized trough planter.

Here they are, all ready for planting!

Chemicals and Organics

As a family, we always try our best to eat organic produce. We definitely had some thoughtful moments during this project.

Is it safe to grow in galvanized metal?

This article from Rodale Organic helped me grok the risks of growing food in metal. Specifically, this quote:

“Due to zinc’s limited bioavailability in soil, there is little chance of ingesting too much zinc through plants grown in proximity to galvanized metal”

We thought for a moment about plastic liners like these (paid link), but is plastic really better than metal?

Styrofoam? Really?

Yeah. We had the same thought. We didn’t find any definitive studies or articles on the topic, but decided that having them in the bottom and having landscaping liner between the soil and the styrofoam made this a low risk situation. If you know something different, please post it in the comments!

Organic Potting Mix

Doh! We would have preferred organic potting mix, but the local home improvement store was out of stock. It’s back in stock now, though, and the price is similar.

Detailed Cost Breakdown

Here’s what we paid for six planters (prices from March 2017):

- Six galvanized stock tanks (paid link): $564

- Six 4-packs of wheels: going with these (paid link): $162

- One roll of landscape fabric (paid link): $23

- A box of 100 ¼”-20 x 1-½” Stainless Steel Hex Head Bolts (paid link): $22

- A box of 100 ¼”-20 Stainless Nylon Insert Lock Nuts (paid link): $13

- Two boxes of 100 ¼” Flat Stainless Steel Washers (paid link): $12

- 15 50 qt. bags of potting mix: $217

- 3 pressure treated 8’ x 5/4” x 6” boards: $19

- Styrofoam from the dump: FREE with strange looks!

Total for SIX: $1,032

Cost for one planter: $172

Cheapify it!

If you’re looking to cut costs on this project, here are a few ideas:

- The biggest expense is the planters. Use an IFTTT recipe to get emails whenever someone posts something on Craigslist that matches search phrases like watering trough, feed trough, stock tank, etc.

- Watch for sales on potting mix / potting soil. That’s the next biggest expense in this project. Don’t use regular old garden soil — it’ll be even heavier and you’ll have drainage problems.

- I suppose you could skip the wheels, and just rest the planters on bricks or stacked wood. I wouldn’t recommend it, though — you’ll be fine the first year, but in a world of hurt from year 2 and on.

What do you think?

Have some ideas of how I could improve the design? Have questions, or pictures of your own planters that you want to share? Put them in the comments below!

And if you liked this write-up, I’d really appreciate a Pin on Pinterest or a like on Facebook!

Some of the links on this page are affiliate links. Please don’t feel obligated to follow them, but I’d definitely appreciate it.

As an Amazon Associate, I earn from qualifying purchases.

This was a great write up for both detail and humor. (You got to keep ’em separated!) Thanks for posting!

Super job doing both the project and the write up! I have been doing this kind of gardening a couple of years. Like you I did the straw and wasn’t to lucky. This tank gardening is great! I have had the best butternut squash and peas. The only thing I’d add is putting fencing around the inside of the container upwards so the birds don’t get to the goodies. Out here I have a lot of them who like to fest on my new plants. I have golfers for a huge problem. I put mine on round pipes so I can roll them around. Nat as easily as your investment though. However, I do have a tractor with forks on it which helps when I go to move them! GOOD JOB All the way around. And thank you for posting!~Suzanne

Awesome write up – just what I was looking for, thanks! I wonder if it would be a little easier to make a wooden frame for the wheels that the tub sits on top of? That would eliminate the back and forth of the bolting, support the bottom of the trough and perhaps a little easier to replace the tub or wheels if something wears out.

Great idea! I was thinking about doing that, but thought I’d save a step. I might have been short-sighted, though!

FYI You can use plants to remove the soil contaminants. http://www.resilience.org/stories/2014-08-11/using-plants-to-clean-contaminated-soil/

I was planning on raising an 8 ft trough on some pressure treated wood, as I think it will simply be way too heavy for wheels. Why do you say that after year 2 I would be in a world of hurt? Because of rotting? Do you think it would be any better to use bricks or cinder blocks? The trough is on solid concrete otherwise, I’m only thinking of raising it to help with drainage.

I say a world of hurt because of the weight of the planters + the soil — you wouldn’t be able to move them if you needed to do so. I just took mine apart and inspected the wheels (after a year of watering + leaving outside for the winter), and they looked great and still rolled around smoothly. But I personally think you’d be fine with pressure treated wood, cinder blocks, or bricks. Good luck!

Thank you for asking this, as I was also wondering. Wheels wouldnt work for us, as they will just settle into the soil/rocks when it rains. I dont care about moving the trough, but wondered what the problem would be about placing the trough on cinder blocks or something similar. Thanks again for asking!

I think that’s a great idea if you don’t need to move them!

Thank you for this! I did one by myself and it took 2.5 hours, mostly because I had bad tape that didn’t hold the bolts well enough. The nutdriver was a life saver and I almost didn’t bury it!

This may seem like a dumb question…but, where do I place the washers? Does one go on the inside of trough on metal and the other on outside bottom on top of wood? Or do both washers go on bottom outside…one on top of wood on bottom of trough and the other between nut and wood.

I started by putting the washers on the inside of the tub, but I ended up having to change the bolts, and the ones I used had square heads that didn’t sit flush inside the washers. If you don’t have that problem, it’s a good idea to put a washer inside and outside, but if you have a big-headed bolt, that should probably be enough. You’ll be able to tell pretty quickly if it’s not working after one or two.

Great write up and very detailed instructions, thank you!

Hi! I love this. I have a old tank that’s rusting on the bottom on lower sides. Should I scrape it and get a new one?

I think if the rust is just on the surface, you should be ok brushing it off and maybe sealing it with a rust sealer spray paint. If it’s started to corrode through, though, I’d get a new one.

Just built 2 of them and thanks to your very helpful instructions, the whole process was smooth and efficient, a couple of hours for each one from measuring the wood to final tightening on the bolts. REALLY useful that you talked about your mistakes – I would have made several, I’m sure i would have tried bolts that were too long and kept the wheels from turning if you hadn’t alerted me to that. Big thanks!!

Glad the instructions helped! I hope you enjoy them as much as we do.

Is there rust on the wheel yet, 2021 now.

Nope! They’ve held up really well, and we just moved them to another area of the yard.

Thank you so much for these detailed instructions, I just might try it. I wonder if anyone following this thread has painted their galvanized troughs? Any thoughts advice, pitfalls to share? I’ve seen some instructions that require a lot of work, don’t really want to do all that to have it fail.

I made mine 3 years ago and did paint the outside with Rustoleum paint. I live on the coast in FL and everything rusts – except for this planter. Even the wheels are still working well. I have had zero issues.

I followed the directions exactly and am very pleased with the result.

I have been thinking of using water troughs for planters on my deck. My deck is on the south side of my home and gets intense heat and sun. I worry that the soil will get too warm and therefore not grow plants well. Do your planters sit in full sun all day? If so, have you experienced any soil problems because of it?

Yup – ours are in full sun all day, and they seem to do really well. It’s nice because we can plant a bit earlier for our zone as well!

If the planters are placed on gravel, do you think you still need to raise them for drainage? Also how many wood/cinderblock/bricks are needed to support adv 8x4x2 planter?

I would raise them, personally. And unfortunately I don’t know how many supports would be needed for that sized planter, but I’d go for more over fewer!

I have 4 troughs and plan on putting them up on blocks as I don’t intend to move them. The problem I’m having is drilling drainage holes🤔

I have the same drill as you and bought a bit specially for going through metal but can’t get drain holes. I got my troughs at Wilco.

Any suggestions?

Yes I’m a 5 foot woman but is there a knack to this drill drainage holes thing?

Feeling like a weakling

Please help😞

Hi Fiona – this article will probably be helpful: https://www.familyhandyman.com/tools/drills/tips-for-drilling-holes-in-metal/

The biggest thing I’ve learned about drilling through metal is that you should start really slow. It’s counter-intuitive since metal is harder than wood, but if you go too quickly your drill might wander. I also don’t use a fancy metal bit — I just use a normal drill bit, and something find that creating a dimple with a punch helps center the bit.

Good luck!

Thank you for the idea! After having saved your post for over 6 months and buying all of the supplies, I finally took advantage of isolation and put one together. Took me about 2 hours, mainly because I kept checking the steps over and over.

Thank you, again.

This is such an awesome idea. I’m taking plenty of notes. I loved where my vegetable garden used to be however it got replaced with a septic mound. I skipped having a garden last year because I didn’t know where to grow another one. This is a perfect solution for me. We like to grow cucumbers, green peppers, green beans and tomatoes. Any veggies that we should not grow together in the same trough? Also have you grown sweet corn or asparagus in them? Are there some veggies that don’t work too great? Finally, do you transplant your veggie in there or the seed? I live in Wisconsin.

Hi – we’re not very adventurous gardeners. Every year, we grow basil, parsley, cilantro, sugar snap peas, potatoes, tomatoes (they keep coming back!), and cucumbers. They all grow perfectly well in these bins. We haven’t grown green peppers, sweet corn, or asparagus. We typically direct seed, and find the soil gets warmer earlier since they’re in containers. Tomatoes and basil we usually transplant. Not sure about co-growing — I’m sure there are some great articles out there about that. Good luck!

Hi Josh, I was wondering if you don’t have access to the straw layer is there something else I can use? Thank you for the step by step instructions, I will be making them this week.

Hi – I would just use good potting soil and compost. Peat moss is pretty light too!

Hi Josh – Loved this DIY – I plan to make one; currently looking for troughs on craigslist. I really like the IFTTT recipe idea. This might be a stupid question – but is there a reason why one might not put the bolts in through the bottom and screw the nuts in from the top? You’re going to cover the nuts with dirt anyway, right? Is there a technical or mechanical challenge that I’m not imagining here?

Also, I had this thought of taking some plastic or metal tubing, make a closed loop, put some micro holes in it and bury it in the soil about 6″ in with one end sticking out. I’m hoping to be able connect a hose to water the trough. Let’s see how that works 🙂

Glad you like it, Vik! They’ve served us well for years now.

The reason I put the nuts on the outside instead of the inside is that I thought the most likely piece that I might need to replace in the future is the wheels, so I thought it would be easier to be able to get to them from the outside. So far I haven’t had to worry about that, though!

Great idea for tubes for watering. We use soaking hoses ourselves (the kind with the small holes in them). We’ve had a heck of a time finding any that would last more than one season, but this year we’re trying these soaker hoses (https://amzn.to/2y0G6A6). The quality is MUCH higher than the cheaper models. We also found that it helps to have a pressure regulator (this one https://amzn.to/2WokYNA) which seems to really help normalize the pressure along the whole length of the hose. Hope that helps!

Is there anything different you can use besides partially composted straw?? Or where would one find partially composted straw??

I wouldn’t worry too much about the straw, it’s just something that we had on hand that I thought would help build the soil. If I were doing it without the straw, I would just do a mix of potting soil and compost, both of which you can buy at a big box store. I was watching a video over the weekend about hugelkultur (https://www.permaculture.co.uk/articles/many-benefits-hugelkultur), which might also be an interesting approach to try in raised structures. The video was about an Australian gardener who uses hugelcultur in metal growing beds, and he seemed very happy with it.

Awesome! Thank you so much for the well written directions. Also, thank you for sharing your tips and pitfalls. The pictures were great and I really appreciate the effort you put into documenting and sharing your project. I plan on making two to place in front of my Saloon/Old West themed garden shed.

I have five galvanized tanks I’ve been growing vegetables in for five or six years now, and I just love them. But I’m wondering how long it takes the bottom to rust out (they’re sitting directly on the ground) because I’m thinking about planting a small fruit tree in the middle each (5’x2′) and I would want the roots to go into the ground under the tank and not interfere with the vegetables. Any ideas?

That’s a great question! I have no idea, but a quick Google search tells me that galvanized metal can take 30+ years to rust through. I might suggest cutting out a hole to make sure the bottom doesn’t interfere with your roots.

I was researching something like this and found your write-up. Very well done and answered a lot of questions, some of which I didn’t know I had!

One idea about watering. I have purchased and thrown out many soaker hoses. They water unevenly and rot out in 1-2 years. I have eight raised bed gardens and I put in drip irrigation. It is not expensive, and it is flexible in terms of changing fittings and water lines as needs change. I use drippers and small spray heads. I run it off of a water spigot with a timer that takes care of watering when I’m traveling. Cheers.

Thank you so much for this! I bought everything except the wood and now I can’t find 6/5 by 6 anywhere in Southern Cal. It’s like they’ve pulled it from the shelves. Is there another standard size for this wood that will work for the hardware you suggested? I’m stuck – I have everything you suggested except the wood!! Help!

I wouldn’t worry about the 6/5! That’s just what we had on hand. If it were me, I’d use a 2 by 6 to make it nice and meaty. Of course, you’ll need to adjust the length of the bolts appropriately!

Josh, thanks for the quick reply! I know I may sound dense, but if I used 2×6, is the “adjusting” I’ll need to do that you mentioned 1) some sortt of adjusting on the bolts you recommended (remember, I bought everything you advised to a “t”) or 2) is it buying new bolts? If the former, I’ll figure it out along thew ay. If the latter, can you send a link to me of what I should buy. I am a DIYer who is good at some things and really deficient in other things. This 6/5 thing had me stumped. It is literally unavailable on the west coast at the moment but completely available on the east coast.

Hi West Coasters – this is a great project with great plans, but pine treated wood is a midwest and east coast thing (not really available out here) and 6/5 is not a standard size so don’t go and click on the links to buy the hardware and think you’ll be able to pick up the wood at a local shop. Instead, you’ll be buying pressure treated Doug Fir out here (not Pine) and probably need to go with 2x6s. I wish I could tell you the hardware, but I haven’t figured out yet.

Great project! So much better than planting in wine barrels which rot away after a few years. I’ve made two mostly using your plans, but with a few added improvements. First, I sealed all bolts on the inside with a layer of caulking to prevent water from leaking into the wood and wheels. Second, I added a 6ft U-shaped conduit frame Bolted to one of the long sides. Stringing nylon string from this frame makes a simple, rugged frame for climbing veggies and it doesn’t shade the ground level veggies. This fall I will also use the frame to support plastic sheeting over the whole trough for a mini, and mobile, greenhouse. With two troughs I put the frames on the outside and there is substantial greenhouse space between them. Third, I used sheep troughs which are the same area, but shorter and considerably lighter. The veggies don’t really need the depth of a full size trough. Fourth, I placed a layer of weed cloth on the bottom topped by one bag of crushed lava rock and another layer of weed cloth. This gives excellent drainage, is light, will last forever, and I don’t need to worry about styrofoam near the veggies. The silicate in the lava rock is actually good for the plants. I hope these thoughts help others. I would upload some pics of these beauties, but I don’t have a website for this. Thanks for getting me started on this Josh!

Fantastic feedback! We may be adding our own trellis / hoop system soon, that’s a great idea. And good idea using the sheep troughs — we picked the ones we picked largely for the look, and totally recognized that they’re taller than needed just for growing the plants. Good stuff!

Josh – I believe this could be improved by changing out the wheel links/recommendations. I had big issues with several sizes of the bolts hitting the wheels. The only solution was a bolt that is actually a bit short. I believe that this could be solved by a different wheel design or a wheel that is adjustable and not fixed. Honestly, that would be one of the biggest time savers. Also, after a few tries and redos. One of the wheels on one side is not hitting the ground and therefore the planter is loopsided. An adjustable wheel would fix that to. Other things that could possibly be addressed: you need a second person to hold one side of the bolt while drilling. Look, overall I’m going to have my two planters, but a “I made six galvanized” v2 would be a good idea. Also, it might be nice to acknowledge that you cannot find pressure treated pine on the west coast. Therefore a west coast recipe could be: 2 x 6 pressure treated Doug fir with 2inch bolts (I know it sounds too short but it isn’t). You could recommend 2 1/4 if the wheels were adjustable.

This may be the best DIY post I’ve read. Appreciate the amount of backstory (not too much), your humor, clear instructions, pictures at multiple stages throughout process, and the links to the tools and supplies are invaluable. Bravo! I’ve been thinking of getting some galvanized tubs for planters and now I’m inspired to make them awesome. Also, the suggestions by other readers in the comments – so great! Thank you fellow commenters!

Hi Josh, one each of my two planters, one of my wheels is raised. Any ideas on how to fix that before I put my soil in? Everything is screwed in so I won’t be able to redo the screwing in of the wheels (actually I already tried on one planter and it happened again and it was a lot of work to re do it).

Planning on doing these and hoping to add a pvc frame to covert to mini greenhouses in the winter. Any suggestions?

Great idea!

What if I used large potting plastic pots in the bottom of the galvanized planters

should the drainage holes go around them

Upside down to fill in space? That’s a good idea. I would put the drainage holes under them.

I purchased seven galvanized troughs at Tractor Supply, low one for squash/ zucchini, one tall long for tomatoes. Should I drill holes in the bottom or just layer the inside with gravel/peat moss/soil? Just need some direction, no wheels on the bottom, just sitting on top of plastic. Live in southwest pa. So we are not quite ready to plant but getting close. Any and all ideas are welcomed.

I think you should drill the holes! More drainage is better, IMO.

Thank you so much for your detailed instructions! With so many folks commenting along this line, I’ll bet you’ve saved this little trough community thousands of hours! I was going to do this anyway but never thought of the casters – a total game-changer! Another website suggested bags of packing peanuts for the bottom, which I thought was brilliant. I don’t worry at all about the styrofoam, as the plants’ root systems will be far above it.

Now to decide what mix of soil/potting soil/manure/compost to put in them! The Self-Sufficient Me YouTube guy uses plain topsoil & compost, but I think that’s way too heavy & dense. How are your planters doing with all potting soil? Seems as if that would require a LOT of frequent watering…

Anyway, THANK YOU!

They’re doing really well with all the potting soil! Over the years, we’ve added a lot of compost, and every bin is chock full of earthworms. So it’s worked quite nicely!

Since you have open space around the styrofoam that’s underneath the landscape fabric and there is already a drainage port near the bottom, why do you need to drill extra drainage holes? Water will drain to the level of the port and there wouldn’t be more than an inch or so left in the bottom. Wouldn’t that be sufficient?

You may be right! I’m really not sure, but this has worked really well.

How has the styrofoam worked out for you after all these years? I have an endless supply of styrofoam, but am really leary about using it. At some point we are going to move, annd not take these pots with us. They will probably be dumped, with styrofoam littering alll the land around here.

Hi Kelly – it’s worked out remarkably well. We made six planters, and only one of them has had problems. Some burrowing creature decided to make a nest in that planter, and they dug up both the dirt and the styrofoam, which made quite a mess. Yeah, disposal will definitely be tricky, but I can’t think of any other material to put in the bottom of these that won’t make them so heavy that they can’t be moved. Good luck!

Thanks for all the suggestions! Not sure if this is still and active thread, but I am wondering if anyone used this method with a 2x2x6 ft tank? Do you need to make adjustments to caster placement (or add anything) to accommodate the 2 feet of length of the tank? Dave Gold mentioned a 6ft U-shaped conduit frame so wondering what size tanks Dave has used.